FIBC Polyester Loop

FIBC Polyester Loop Specification

- No Of Ply

- 1

- Tensile Strength

- High

- Density

- Gram per cubic centimeter(g/cm3)

- Construction

- Woven

- Capacity

- Supports up to 2 Ton (2000 kg)

- Material

- Polyester

- Type

- Loop

- Texture

- Smooth

- Style

- Plain

- Application

- FIBC Bags, Bulk Bag Lifting

- Diameter

- Customized

- Thickness

- Standard

- Length

- Customized

- Characteristics

- High strength, Durable, UV resistant

- Ply

- Single

- Color

- White

- Shape

- Flat/round

- Size/Dimensions

- As per requirement

- Temperature Resistance

- -20°C to +70°C

- Recyclability

- Yes

- Finish

- UV treated/Untreated options available

- Abrasion Resistance

- Excellent

- Elongation at Break

- Less than 15%

FIBC Polyester Loop Trade Information

- FOB Port

- Ahmedabad

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Box

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa, Asia

- Main Domestic Market

- All India

About FIBC Polyester Loop

Product Details:

| Usage/Application | Industrial |

| Design | White |

| Material | PP |

| Pattern | Plain |

| Brand | Bonus |

| No Of Loops | 4 |

BPPL provides Polyester loops which are extensively used in FIBC industry as Jumbo bag handles.

Our expertise lies in providing high strength polyester belts with superior weave and finish.

Superior Strength and Durability

Our polyester loops are designed for robust performance in FIBC bags, supporting loads up to 2 tons. Constructed to resist abrasion and UV damage, they offer long-lasting reliability, making them ideal for demanding industrial use.

Customizable for Your Needs

You can specify diameter, length, shape (flat or round), and finish (UV treated or untreated). This high level of customization ensures optimal compatibility with your bulk bag lifting and storage requirements.

Eco-Friendly and High Performance

With excellent recyclability and a low elongation at break, these loops assure both environmental responsibility and dependable function, even in temperature extremes. Their smooth, plain texture enhances handling efficiency and safety.

FAQs of FIBC Polyester Loop:

Q: How are FIBC Polyester Loops typically used?

A: FIBC Polyester Loops are primarily utilized for lifting and transporting bulk bags (FIBCs), providing robust and secure support for loads up to 2 tons in industrial and commercial settings.Q: What are the main benefits of using polyester loops with temperature resistance from -20C to +70C?

A: These loops maintain their high strength and integrity across a wide temperature range, ensuring reliable performance in both cold storage and high-heat environments, making them suitable for diverse operational requirements.Q: When should I choose a UV treated finish for my loops?

A: Opt for the UV treated finish if the loops or attached FIBC bags will be stored or operated in areas exposed to sunlight, as it helps prevent degradation and extends product lifespan.Q: Where can these polyester loops be customized according to my requirements?

A: Customization requests for diameter, length, shape, and finish can be fulfilled by our production facilities in India, catering to exporters, manufacturers, and suppliers globally.Q: What is the manufacturing process involved in making these FIBC polyester loops?

A: The process typically involves weaving high-strength polyester yarns into a smooth, single-ply loop construction, followed by optional UV treatment and cutting to custom sizes and specifications.Q: How does the loops abrasion resistance benefit daily operations?

A: Excellent abrasion resistance ensures that the loops withstand rough handling and repeated use, minimizing wear and extending their usability for lifting and transporting heavy loads.Q: What makes these polyester loops environmentally friendly?

A: Being fully recyclable, the polyester loops not only reduce environmental impact at the end of their service life but also promote sustainability within bulk packaging operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polypropylene & Nylon Webbing Belts Category

Polypropylene Bag Closing Thread

Type : Other, Bag Closing Thread

Thickness : Standard

Size/Dimensions : Custom available

Style : Other, Twisted

Density : 0.93 Gram per cubic centimeter(g/cm3)

Tensile Strength : High

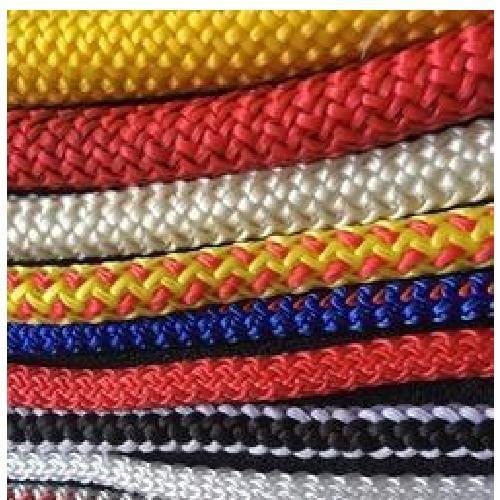

Polypropylene Braided Cord Ropes

Type : Other, Braided Cord Rope

Thickness : Varies as per requirement

Size/Dimensions : Standard and customizable dimensions available

Style : Other, Solid Braided

Density : 0.91 Gram per cubic centimeter(g/cm3)

Tensile Strength : Up to 7500 kgf (varies by diameter)

PP Multifilament Yarn

Type : Other, Multifilament Yarn

Thickness : Fine to Medium

Size/Dimensions : Customizable

Style : Other, Twisted or Flat

Density : 0.91 Gram per cubic centimeter(g/cm3)

Tensile Strength : 4.85 g/denier or as specified

Rigid Webbing

Type : Other, Rigid Webbing

Thickness : 0.5 mm to 5 mm (customizable)

Size/Dimensions : Width: 10 mm to 100 mm (custom available)

Style : Other, Plain, Woven, Herringbone, Patterned

Density : 1.4 Gram per cubic centimeter(g/cm3)

Tensile Strength : Up to 4500 kg (varies by width and material)

GST : 24AAACB4753C1Z7

|

|

BONUS PLASTIC PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry