Rigid Webbing

Rigid Webbing Specification

- Density

- 1.4 Gram per cubic centimeter(g/cm3)

- Tensile Strength

- Up to 4500 kg (varies by width and material)

- Capacity

- Depends on application and width/material

- No Of Ply

- Single, Two Ply, Three Ply

- Construction

- Woven or Knitted

- Material

- Polyester, Nylon, Polypropylene, Cotton, Custom blend

- Type

- Rigid Webbing

- Texture

- Smooth, Textured, Patterned

- Style

- Plain, Woven, Herringbone, Patterned

- Application

- Straps, Luggage, Safety Harness, Outdoor Gear, Industrial Use, Apparel Accessories

- Thickness

- 0.5 mm to 5 mm (customizable)

- Length

- Standard 50 m rolls, Custom lengths on request

- Characteristics

- High tensile strength, Low stretch, Abrasion resistant, UV Resistant, Durable

- Ply

- Single and Multi Ply

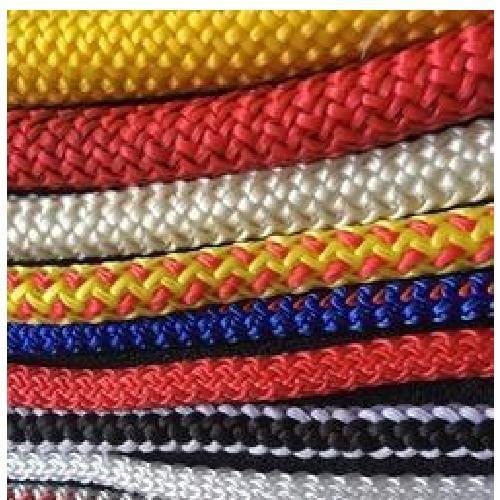

- Color

- White, Black, Blue, Custom available

- Shape

- Flat, Tape

- Size/Dimensions

- Width: 10 mm to 100 mm (custom available)

- Finish

- Colorfast, Water repellent, Flame retardant (optional)

- Pattern/Design Options

- Solid, Stripes, Jacquard logo possible

- Temperature Resistance

- -40°C to 120°C (material dependent)

- Edge Type

- Heat cut, Ultrasonic cut, Sewn finish available

- Weight

- 10-60 g/m (as per width and material)

- Compliance

- REACH, RoHS and ISO certified manufacturing

- Packaging Type

- Rolls, Bundles, as per customer demand

- MOQ

- 500 meters per size/color

About Rigid Webbing

Application Areas:

- Strings for mattress edge wrapping

- Decorative bands in trousers and sleeve of fashion and children garments

- As for color flat webbing in cases and bags, shoes and hats, strings

- As twin-strings in garments and bag edges

- As PP threads (pure terylene) and PP (Naslon fiber) cords in trouser belts, cases, and bags, strings

- As round jacquard cords in mobile phones, tapes, and strings.

Product Details:

| Brand | Bonus |

| Colour | Plain Black, Natural White and other 25 shades |

| Material | Polyester Narrow Woven Fabrics and PP Woven |

| Packaging Type | Roll |

| Width | 5 mm to 110 mm |

| Thickens | 0.5 mm to 3.0 mm |

Customizable and Reliable Solutions

Our rigid webbing solutions offer unmatched flexibility in terms of width, material, color, finish, and pattern. Whether you need solid colors, stripes, or a jacquard logo, we deliver materials tailored to your requirements. With a minimum order quantity of 500 meters per size and color, customers can choose from standard or custom lengths, along with their preferred packaging type.

Built for Performance and Safety

Designed to withstand extreme temperatures from -40C to 120C, resistant to abrasion, water, UV rays, and low stretch, our webbing meets stringent industry standards. Optional flame retardant properties and colorfast finishes ensure safety and visual appeal over long-term use, making it the ideal choice for both functional and aesthetic applications.

FAQs of Rigid Webbing:

Q: How is the rigid webbing manufactured and finished?

A: Rigid webbing is manufactured using woven or knitted constructions from materials such as polyester, nylon, polypropylene, cotton, or customized blends. Edge types can include heat cut, ultrasonic cut, or sewn finishes, with optional colorfast, water repellent, or flame retardant treatments, depending on customer needs.Q: What are the available size and pattern options for this webbing?

A: Widths range from 10 mm to 100 mm, with custom widths available. Patterns can be solid, striped, jacquard logo, or herringbone. Thickness is customizable from 0.5 mm to 5 mm, ensuring each order matches specific project requirements.Q: When should I choose flame retardant or water repellent finishes?

A: Choose a flame retardant finish for webbing used in high-risk environments or those requiring extra fire safety compliance. Water repellent finishes are recommended for outdoor gear or applications exposed to moisture for added durability and performance.Q: Where can this rigid webbing be used?

A: It is suitable for use in straps, luggage, safety harnesses, industrial applications, outdoor equipment, and apparel accessories. The webbings strength and durability make it ideal for demanding environments.Q: What benefits does the webbing offer for industrial applications?

A: This webbing provides high tensile strength (up to 4500 kg), low stretch, UV resistance, and excellent abrasion resistance, delivering long-term performance and safety in industrial and safety-critical environments.Q: How can I order custom colors, sizes, or patterns?

A: You can request custom solutions by specifying your requirements, such as width, thickness, color, finish, and pattern. The minimum order is 500 meters per size or color, and orders can be packed in rolls or bundles according to your preference.Q: What certifications and compliances are maintained during production?

A: Our manufacturing complies with REACH and RoHS directives, and is ISO certified, ensuring high standards of quality, environmental safety, and product reliability for all webbing produced.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polypropylene & Nylon Webbing Belts Category

Polypropylene Bag Closing Thread

Thickness : Standard

Application : Bag Stitching, Closing HDPE/PP/Jute Bags

Material : Polypropylene

Length : 20005000 meters per spool

Texture : Other, Smooth

Type : Other, Bag Closing Thread

Polypropylene Braided Cord Ropes

Thickness : Varies as per requirement

Application : Marine, Fishing, Packing, Industrial, Agriculture

Material : Polypropylene

Length : Custom lengths up to 500 meters

Texture : Other, Smooth

Type : Other, Braided Cord Rope

FIBC Polyester Loop

Thickness : Standard

Application : FIBC Bags, Bulk Bag Lifting

Material : Polyester

Length : Customized

Texture : Other, Smooth

Type : Other, Loop

PP Multifilament Yarn

Thickness : Fine to Medium

Application : Weaving, Sewing, Net Making, Industrial Fabrics, Rope & Twine Manufacturing

Material : Other, Polypropylene (PP)

Length : As per requirement; typically 500 m to 5000 m per spool

Texture : Other, Smooth and Soft

Type : Other, Multifilament Yarn

GST : 24AAACB4753C1Z7

|

|

BONUS PLASTIC PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry