Narrow Webbing

Narrow Webbing Specification

- Yarn Count

- Varies; typically 150D, 300D, or 600D

- Technics

- Woven

- Fabric Texture

- Smooth or Ribbed depending on style

- Fabric Type

- Narrow woven fabric

- Density

- 800 Gram per cubic centimeter(g/cm3)

- Weight

- 10 g/m to 45 g/m (variable by width and material)

- Shrinkage

- Below 3%

- Fabric Capacity

- High load bearing, up to 500 kg depending on width and yarn

- Material

- Polyester / Nylon / Cotton blend

- Fabrics Character

- High Tenacity, Durable, Flexible

- Style

- Plain, Jacquard, Twill optional

- General Instructions

- Store in cool, dry place; avoid direct sunlight; recommended hand wash

- Length

- Customized as per requirements

- Width

- Typically ranges from 10 mm to 100 mm

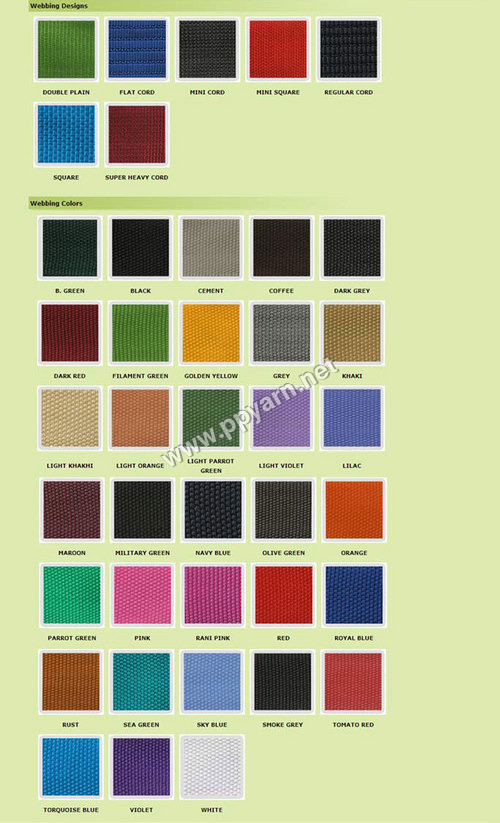

- Color

- Available in multiple colors and customization

- Elongation Rate

- Low to moderate, depending on yarn and weave

- Surface Finish

- Matte or glossy finish available

- Applications

- Garments, luggage, safety harnesses, bags, belts, sportswear, industrial uses

- Resistance Properties

- Resistant to UV rays, mildew, and chemicals (polyester and nylon)

- Printing/Branding

- Custom printing and logo options available

- Packing Type

- Rolls, spools, or cut-length packs available

- Temperature Tolerance

- -40°C to 120°C (varies by material)

- Edge Type

- Heat cut, Ultrasonic cut, Woven-edge, or Knife cut

- Minimum Order Quantity (MOQ)

- 500 meters or as specified

- Recyclability

- Depends on fiber content; polyester/nylon options are recyclable

About Narrow Webbing

Since our inception in the year 1988, we have successfully been engaged in manufacturing, exporting and supplying the best quality Narrow Webbing. The offered webbing is designed and woven under the stern guidance of dexterous professionals with the use of sophisticated webbing machinery. The provided webbing is widely used in different kinds of furnitures as a base owing to its high flexibility. Also, used for improving elasticity and resilience, this webbing is made available in different sizes and thickness. In addition, our clients can purchase this Narrow Webbing at reasonable prices from us.

Features:

- Supreme finish

- High durability

- Soft texture

- Known for elasticity

High Performance & Durability

The narrow webbings construction using robust polyester, nylon, or cotton blends ensures excellent strength and wear resistance. With high load-bearing capacity and low shrinkage, it handles rigorous use in safety, industrial, and fashion applications without compromising on flexibility.

Customizable Quality & Specifications

Available in various widths, lengths, styles, and finishes, our narrow webbing can be tailored for specific needs. Options such as matte or glossy finishes, custom logos, and multiple edge types offer versatility for branding, aesthetics, and function across diverse industries.

Environmental Resistance & Longevity

Designed to perform in extreme environments, our narrow webbing resists UV degradation, mildew, and chemical exposure. It sustains its integrity and appearance from -40C to 120C, making it a reliable choice for both indoor and outdoor uses.

FAQs of Narrow Webbing:

Q: How do I choose the right edge cut for my application?

A: Edge typesheat cut, ultrasonic, woven-edge, or knife cutshould be selected based on your products functional and aesthetic needs. For fray resistance and smoother handling, heat and ultrasonic cuts are preferred, while woven-edge offers maximum durability and a clean finish for visible applications.Q: What are the main advantages of using your narrow webbing in industrial or safety equipment?

A: Our webbing is engineered for high tenacity and load-bearing capacity, supporting up to 500 kg depending on width and yarn. Its resistance to UV rays, mildew, and chemicals ensures reliability and longevity, making it ideal for harnesses, belts, and safety gear.Q: When and where can I use this webbing for customized branding?

A: Custom printing and logo options are available, allowing you to showcase your brand on any garment, bag, or industrial product. These options are suitable at any stage of your production process and are particularly effective for promotional, retail, and uniform applications.Q: What is the manufacturing process for your narrow webbing?

A: We use advanced weaving techniques with high-quality yarns such as 150D, 300D, or 600D. The fabric is then cut, finished, and, if requested, printed or branded before being packed in rolls, spools, or custom cut-lengths ready for delivery.Q: How does the webbings elongation rate affect its usage?

A: With a low to moderate elongation ratedependent on yarn and weavethe webbing provides sufficient flexibility while minimizing stretch under load. This makes it highly suitable for load-bearing applications where controlled elasticity is crucial.Q: What are the environmental and care instructions for maintaining the webbings quality?

A: Store the webbing in a cool, dry area and avoid prolonged exposure to direct sunlight. For optimal longevity, hand washing is recommended. Polyester and nylon options are recyclable depending on local recycling facilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Narrow Woven Fabrics Category

Narrow Fabric Weaving

Width : Up to 12 inches (30 mm)

Weight : Approximately 5100 g/m depending on type

General Instructions : Other, Hand wash or machine wash at low temperature, avoid harsh chemicals

Fabric Texture : Other , Smooth, soft finish

Fabric Type : Woven Narrow Fabric

Fabrics Character : Other, Durable, high tenacity, uniform strength

Narrow Woven Fabric

Width : 10 mm to 50 mm

Weight : Medium to heavy weight

General Instructions : Other, Suitable for industrial and commercial use; avoid harsh chemicals during cleaning

Fabric Texture : Other , Smooth to slightly textured

Fabric Type : Narrow Woven Fabric

Fabrics Character : Other, High Strength, Durable

Woven Webbing

Width : 10 mm to 100 mm (as required)

Weight : 10 gsm to 120 gsm (subject to width and material)

General Instructions : Other, Suitable for outdoor and industrial applications; avoid sharp bending to maintain integrity

Fabric Texture : Other , Smooth or Textured finish

Fabric Type : Woven

Fabrics Character : Other, High strength, flexible, durable

GST : 24AAACB4753C1Z7

|

|

BONUS PLASTIC PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry