Woven Webbing

Woven Webbing Specification

- Fabric Capacity

- Supports up to 3000 kg (material dependent)

- Density

- Gram per cubic centimeter(g/cm3)

- Weight

- 10 gsm to 120 gsm (subject to width and material)

- Fabric Type

- Woven

- Shrinkage

- Low, <2% under normal conditions

- Yarn Count

- Varies depending on webbing type

- Fabric Texture

- Smooth or Textured finish

- Material

- Polyester, Nylon, or Cotton

- Fabrics Character

- High strength, flexible, durable

- Style

- Plain and Twill available

- General Instructions

- Suitable for outdoor and industrial applications; avoid sharp bending to maintain integrity

- Width

- 10 mm to 100 mm (as required)

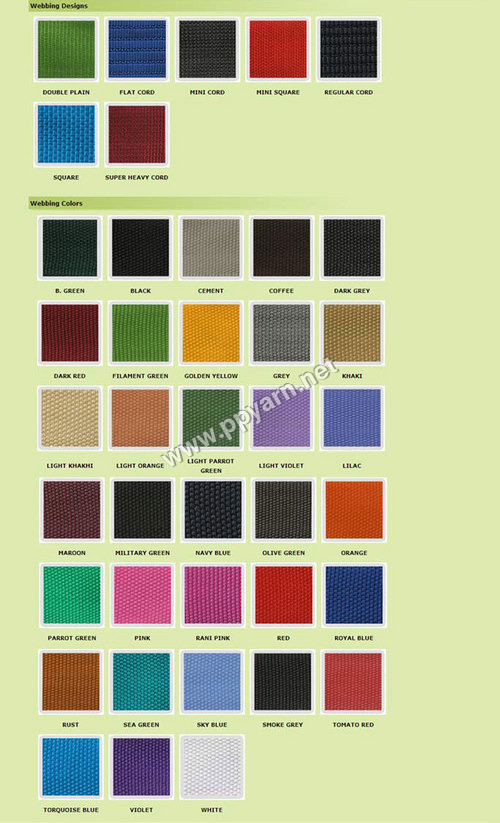

- Color

- Available in Black, White, Red, Blue, Green and Custom Shades

About Woven Webbing

Features:

- Light weight and high stress bearing capacity

- Highly flexible

- No absorption of oil, water, grease etc.

Application of Polypropylene and Nylon Webbings :

Sport Bags : Ruck Sack, Ski Bags, Bowling Bags, Gear Bags, Scuba Diver Bags and Shoe Bags

School Bags : Casual Bags, Back Packs and Duffel Bags

Outdoor Bags : Luggage Bags, Collar Bags, Lunch Bags and New Carter Bags

Health Care : Surgery, Adjusting Straps and Wrist Braces

Automotive : Straps on Cover and Spare Wheel Straps

Aerospace : Anti Static Webbing and Non Inflammable Webbing

Helmets : Suspension Web and Tapes

Filters : Fine Mono Foil Tubular Webbing

Clothing : Trouser Belts, Waist Bends, Back Neck and Suspenders

Military : Trucks, Bedding and Cartridge Belts

Tool Bags : Computer Tool Bags and CD Cases

Others : Slings, Fire Retardant, Safety Belts, Parachute Harnesses, Jumbo Bags, Tents, Lanyards, Snatch Straps, Furniture Belts and Saddler Belts

Superior Durability and Strength

Designed for reliability, our woven webbing withstands heavy loads, supporting up to 3000 kg based on material and width. Thanks to high-quality polyester and nylon yarns, it delivers remarkable tensile strength, excellent flexibility, and enduring performance even under demanding applications. Its resistance to stretching ensures stable load carriage and safety.

Versatile Applications Across Industries

From seat belts and safety harnesses to outdoor gear and industrial straps, our webbing addresses varied market needs. Its weather-resistant, low-shrinkage construction makes it ideal for both indoor and outdoor use, and the option for fire retardant treatment extends its suitability to critical safety environments.

Customizable Styles and Finishes

Choose between plain and twill weaving styles, with a selection of smooth or textured finishes, depending on your requirements. Webbing is available in a diverse color palette, including black, white, red, blue, green, and custom shades, and can be tailored to specific dimensions and yarn counts to match different application needs.

FAQs of Woven Webbing:

Q: How is woven webbing manufactured for strength and durability?

A: Woven webbing is produced using high-quality polyester, nylon, or cotton yarns in either plain or twill weaves. The tight weaving process grants the webbing high tensile strength, flexibility, and minimal stretch, ensuring stability and durability for demanding applications.Q: What are the main applications of woven webbing?

A: This product is widely used in seat belts, cargo straps, harnesses, backpacks, safety equipment, and more, owing to its robust construction, high load-bearing capacity, and resistance to environmental factors such as moisture, UV light, and mildew.Q: When should fire resistant webbing be requested?

A: Fire retardant treatment is available upon request and should be specified for applications where enhanced safety is essential, such as industrial settings, emergency equipment, or environments with fire risk.Q: Where can woven webbing be utilized most effectively?

A: Woven webbing excels in both outdoor and indoor industrial settings. Its environmental durability makes it ideal for harsh conditions, such as outdoor safety gear, while its flexibility and strength are perfect for transportation and load restraint systems.Q: What process should be followed to order custom webbing?

A: To order custom webbing, specify the desired width (between 10 mm and 100 mm), color (standard or custom shades), material (polyester, nylon, or cotton), weave style (plain or twill), and if fire retardant treatment is needed. Reach out to us as an exporter, manufacturer, supplier, or retailer in India for tailored solutions.Q: How should woven webbing be used and maintained for longevity?

A: Avoid sharp bending to maintain the webbings structural integrity. Store in a dry area and clean with mild soap and water as required. Routine inspection is recommended, especially when used in safety-critical or high-load applications, to ensure continued strength and performance.Q: What are the benefits of selecting woven webbing over other materials?

A: Woven webbing offers superior strength, flexibility, and durability, with excellent resistance to UV rays, moisture, and mildew. Its customizable features, such as width, color, finish, and fire retardancy, provide tailored solutions across numerous industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Narrow Woven Fabrics Category

Narrow Webbing

Fabric Capacity : High load bearing, up to 500 kg depending on width and yarn

Style : Other, Plain, Jacquard, Twill optional

Length : Customized as per requirements

General Instructions : Other, Store in cool, dry place; avoid direct sunlight; recommended hand wash

Weight : 10 g/m to 45 g/m (variable by width and material)

Fabric Type : Narrow woven fabric

Narrow Woven Fabric

Fabric Capacity : High loadbearing

Style : Other, Plain, Twill

Length : Customizable as per requirement

General Instructions : Other, Suitable for industrial and commercial use; avoid harsh chemicals during cleaning

Weight : Medium to heavy weight

Fabric Type : Narrow Woven Fabric

Narrow Fabric Weaving

Fabric Capacity : Bulk production available as per order

Style : Other, Plain, Jacquard, Twill

Length : Customizable as per requirement

General Instructions : Other, Hand wash or machine wash at low temperature, avoid harsh chemicals

Weight : Approximately 5100 g/m depending on type

Fabric Type : Woven Narrow Fabric

GST : 24AAACB4753C1Z7

|

|

BONUS PLASTIC PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry